Are you curious about milling machine tools and how they work? Well, let me break it down for you in a simple way. Milling machine tools are powerful devices used in the manufacturing industry to shape and cut various materials with precision.

The Basics of Milling Machine Tools

Milling machine tools consist of a rotating cutter that removes material from a workpiece to create the desired shape or form. These machines can be operated manually or through computer numerical control (CNC) systems, allowing for precise and efficient machining processes.

With different types of cutting tools available, such as end mills, face mills, and ball nose cutters, milling machines can perform various operations like drilling, slotting, contouring, and more. This versatility makes them indispensable in industries like automotive manufacturing, aerospace engineering, and even hobbyist workshops.

The Power of 5 Axis Machining

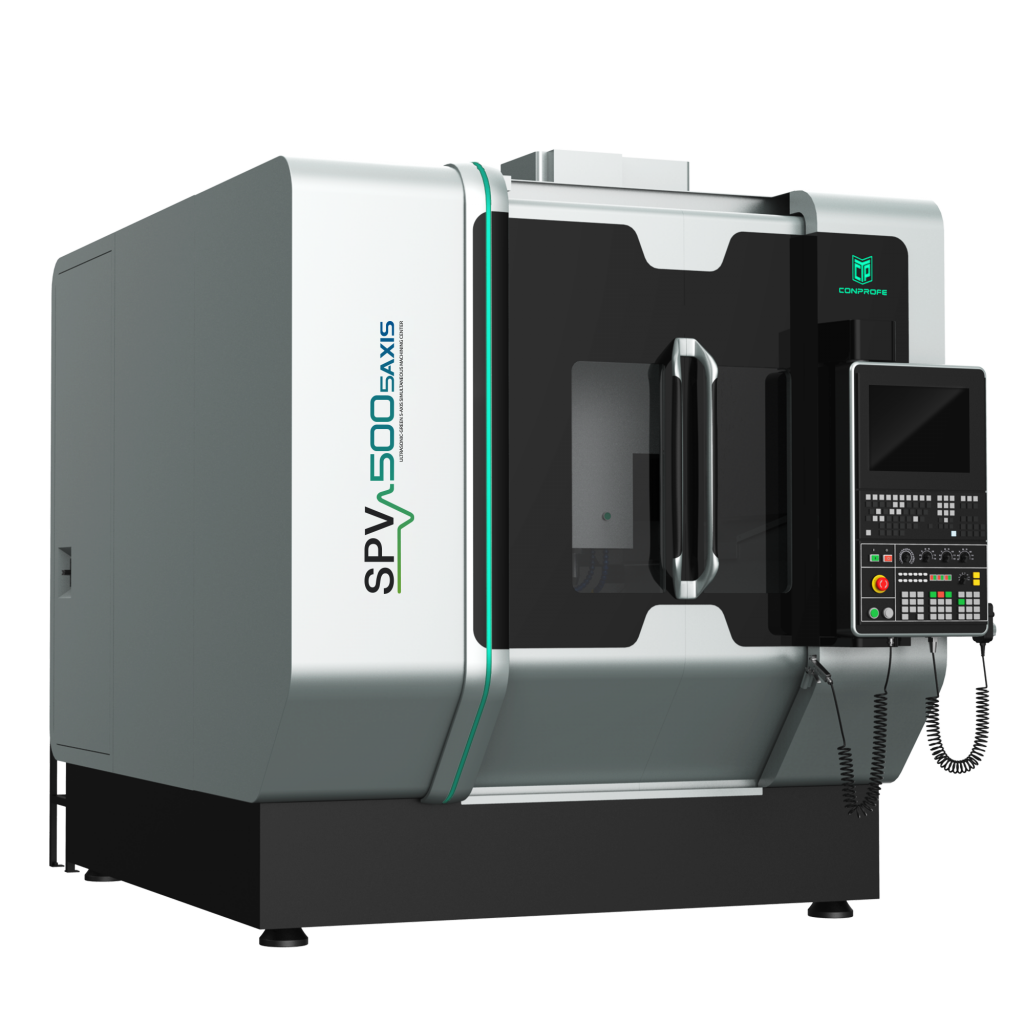

One remarkable advancement in milling machine technology is the introduction of 5 axis machining. Unlike traditional 3 axis machines that move along three linear axes (X,Y,Z), 5 axis machines add two rotational axes (A,B) to provide greater flexibility during machining operations.

This additional freedom allows for complex geometries to be machined with ease. Whether it’s sculpting intricate designs on metal surfaces or creating precisely angled cuts on composite materials – 5 axis machining opens up new possibilities for manufacturers seeking highly accurate results.

Innovations by Conprofe Ultrasonic

A notable player in the field of milling machine tool innovation is Conprofe Ultrasonic. They have developed cutting-edge ultrasonic-assisted machining technology that enhances the performance of conventional milling processes.

By introducing high-frequency vibrations into the machining process, Conprofe Ultrasonic’s tools reduce cutting forces and improve material removal rates. This results in reduced tool wear, improved surface finish, and increased productivity for clients across various industries.

Furthermore, their ultrasonic-assisted milling technology enables the machining of hard-to-cut materials like titanium alloys and hardened steels with greater ease and efficiency.

In Conclusion

Milling machine tools are essential equipment in modern manufacturing processes. From basic operations to advanced techniques like 5 axis machining and ultrasonic-assisted milling, these tools offer precision, versatility, and tailored solutions for clients’ specific needs.

So whether you’re a hobbyist looking to create intricate designs or an industrial manufacturer seeking efficient production methods – milling machine tools have got you covered!

-1-1024x919.png)